The pandemic has put extreme pressures on many businesses, and protecting profitability is of vital concern. The jury is still out on long-term inflation, but for now, we must deal with escalating material costs and shortages as well.

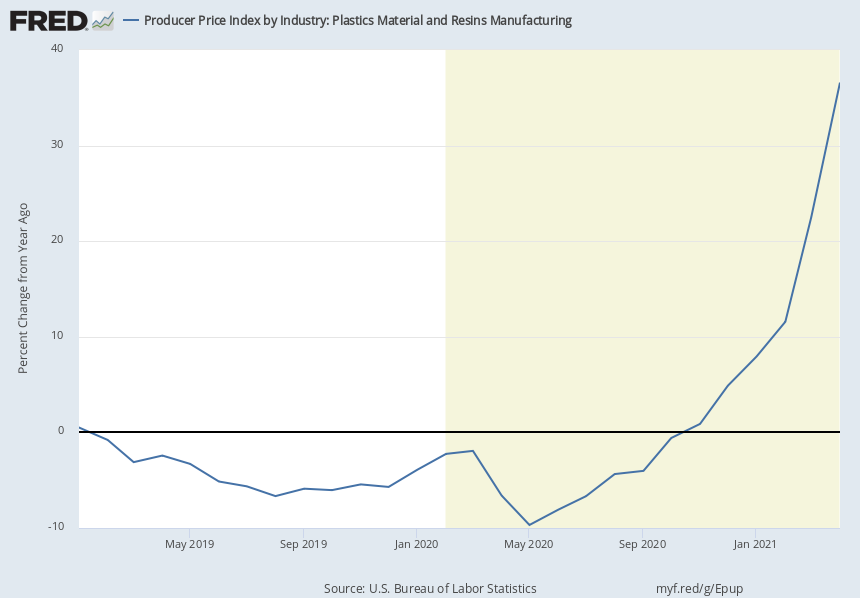

Lumber, steel, resin, microchips and precious metals make most of the headlines, but the increases are everywhere. Paired with higher transportation costs, container shortages, and supplier shortfalls, it is apparent that this is causing many businesses already. It is evident the devastation this is causing to many companies with low inventory levels. Most importantly, companies are looking for workers, and this competition is causing labor costs to rise.

The question becomes what is the best course of action to “Protect Profitability”?. The easy solution is to increase the selling prices of your products, which your competitors will do also. This approach will only keep your organization equal with your competition. I would take the stance of developing a long-term competitive advantage through a disciplined product cost take-out (PCTOs) process. This combined with some level of selling price increase, will give you a leg up on the competition. Ultimately that manager has ownership of that product, thus holding them accountable for meeting their goals. This continuing process becomes annual, not just a stop-gap measure in times of the current cost pressure.

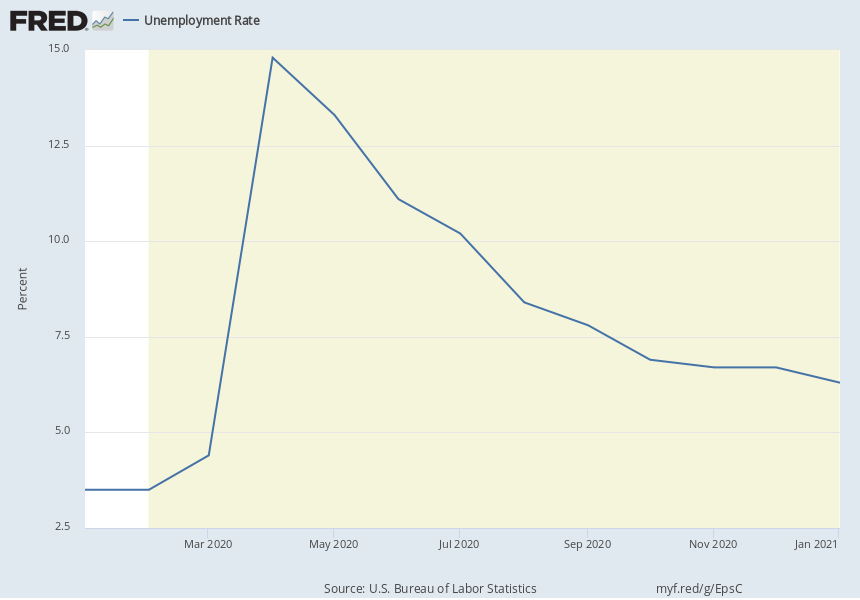

The starting point is for the product line manager and the executive team to understand the key performance indicators (KPIs) driving the product cost – both general economic and internal KPIs. The external KPIs are those that your organization and your competition face (see the graphics below).

How you gain your competitive advantage is through driving improvement in your internal KPIs. Here are some examples:

From a Labor Perspective

- Labor productivity improvements

- Reduce labor content through automation

- Can we use sub-assemblies from our supplies, thus pushing back some of the work to the supply chain?

From a Material Perspective

- Can we get a better yield from the material we are processing?

- Can we find ways to reduce scrap?

- Alternate material and alternate vendors – by being blindly loyal to your current vendors, you could be missing an opportunity

These are examples of internal metrics that need to be monitored and managed for the products you are producing. To take this a step further, set goals for continuous improvement in these metrics. When you meet the goal – reset the goal for further improvement. This will establish a culture of constant advancement in your organization – keep in mind “if your organization is not continually improving, you are losing ground to your competition.” Pay close attention and listen with a keen ear to employees closest to the product – those on the floor producing it. They are your best source of product and process improvement ideas.

At CDH, our Executive Focus service offering is all about making your internal metrics come alive. We help companies monitor and manage their KPIs in a unique format to drive continuous improvement. If you would like to learn more about our Executive Focus process, please contact Matthew Wirth, Senior Manager of Consulting, at [email protected] or 262.784.4040.